Glass bottles are a staple in many industries, from beverages to cosmetics. Understanding their composition is critical to ensuring quality and performance in a variety of applications. Here is a detailed breakdown of what glass bottles are made of:

Main Ingredients

- Silicon dioxide (SiO2)

- Source: usually derived from sand.

- Function: forms the structure of the glass network and provides the main material for glass manufacturing.

- Soda Ash (Na2CO3)

- SOURCE: Derived from the natural mineral natural soda ash or from synthetic processes.

- Effect: lowers the melting point of silica, making glass easier to form and mold.

- Limestone (CaCO3)

- Source: Derived from natural limestone deposits.

- Function: Improves the durability and chemical resistance of glass.

- Aluminum oxide (Al2O3)

- Source: Added from feldspar or recycled glass.

- Function: Increases the strength and weatherability of the glass.

Secondary Ingredients

- Colorant

- Type: iron, chromium, cobalt and sulfur compounds.

- Function: Provides a variety of colors for aesthetic and functional purposes, such as UV protection of contents.

- Crushed glass (recycled glass)

- Source: Glass recovered from manufacturing defects or post-consumer waste.

- Role: Reducing the energy required for melting, promoting sustainability and cost efficiency.

Manufacturing Process

- Batch mixing

- All raw materials are accurately weighed and mixed together to form a homogeneous batch.

- Melting

- Batches are melted in a furnace at a temperature of approximately 1,700°C (3,092°F) to form molten glass.

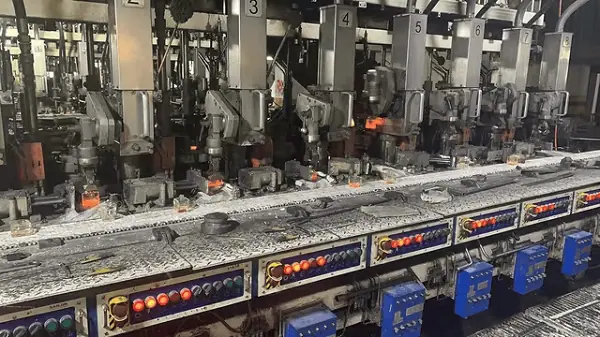

- Molding

- Molten glass is molded into bottles using processes such as blowing or pressure blowing, depending on the desired bottle shape and size.

- Annealing

- Formed bottles are slowly cooled in an annealing furnace to remove internal stresses and ensure durability and structural integrity.

- Inspection and quality control

- Prior to packaging and shipping, bottles are rigorously inspected for defects and conform to quality standards.

Conclusion

Glass bottles are made from a combination of natural minerals and recycled materials that are melted and molded into durable, versatile containers. Precise formulations and manufacturing processes ensure that the final product meets strict quality standards, making it ideal for a wide range of applications.

By understanding the composition and production of glass bottles, companies can better understand the value of these containers and the importance of maintaining high quality standards in the supply chain.